Rubber and plastic heat preservation methods on air-conditioning pipes, manifestations and prevention measures of common defects in heat preservation quality

- Categories:Company News

- Author:

- Origin:

- Time of issue:2019-11-14 14:40

- Views:

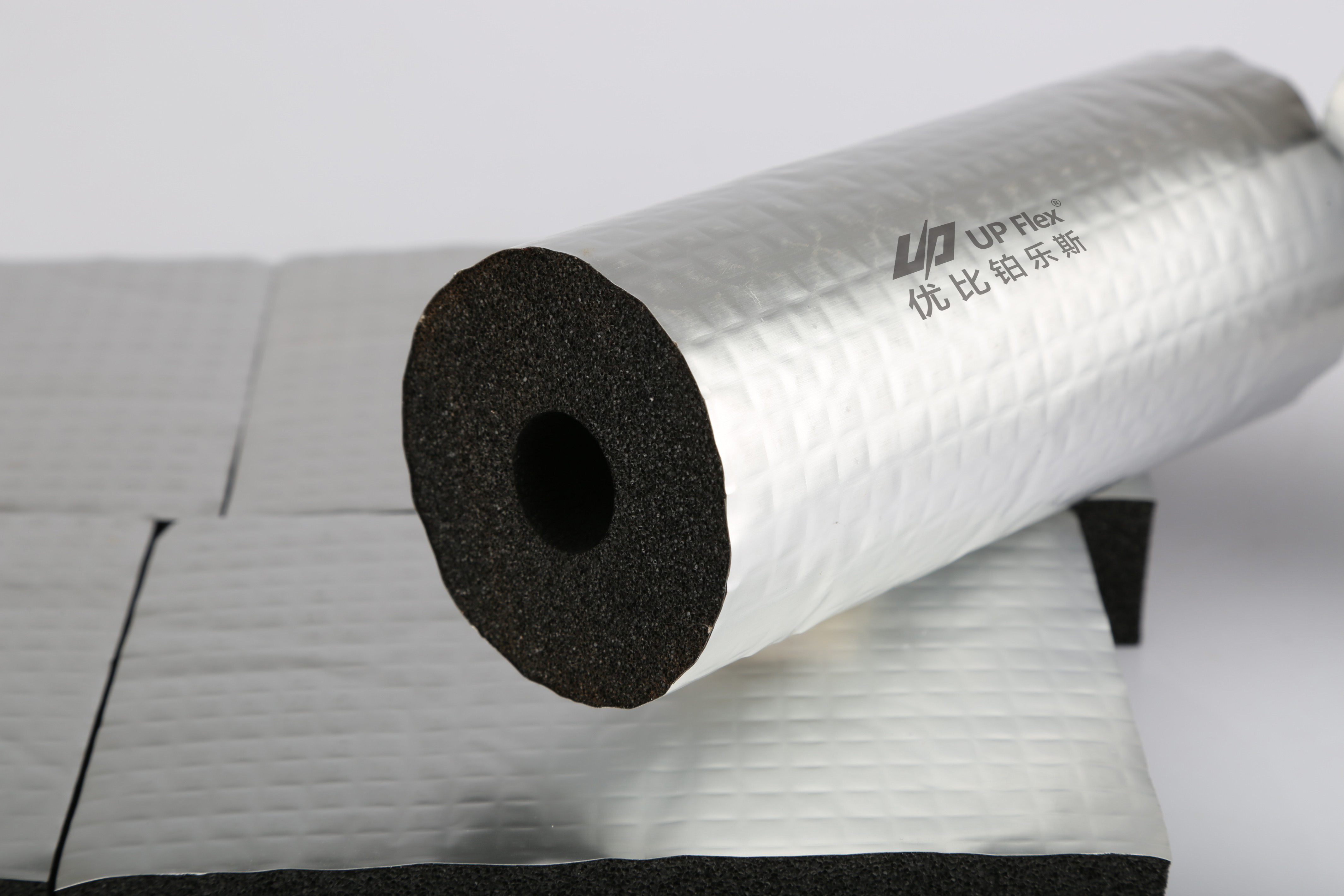

(Summary description)Rubber-plastic thermal insulation material is a kind of thermal insulation material, its material has good thermal insulation effect, and the insulation thickness used for the same pipeline is thin, and the amount is small; it is an integrally formed thermal insulation material, the process is relatively simple, and the progress is fast; it is green, environmentally friendly, and clean. Materials, there are less wastes in construction, which is harmless to health. It is more and more widely used in the insulation of refrigerant pipes and condensate pipes of air-conditioning refrigeration systems

Rubber and plastic heat preservation methods on air-conditioning pipes, manifestations and prevention measures of common defects in heat preservation quality

(Summary description)Rubber-plastic thermal insulation material is a kind of thermal insulation material, its material has good thermal insulation effect, and the insulation thickness used for the same pipeline is thin, and the amount is small; it is an integrally formed thermal insulation material, the process is relatively simple, and the progress is fast; it is green, environmentally friendly, and clean. Materials, there are less wastes in construction, which is harmless to health. It is more and more widely used in the insulation of refrigerant pipes and condensate pipes of air-conditioning refrigeration systems

- Categories:Company News

- Author:

- Origin:

- Time of issue:2019-11-14 14:40

- Views:

rubber and plastic insulation material is a kind of thermal insulation material, its material has good thermal insulation effect, and it is used for the same pipeline The thermal insulation thickness is thin and the amount is small; it is an integrally formed thermal insulation material, the process is relatively simple, and the progress is fast; it is a green, environmentally friendly, and clean material, with less waste during construction and harmless to health. It is more and more widely used in the insulation of refrigerant pipes and condensate pipes of air-conditioning refrigeration systems.

Material performance:

rubber-plastic insulation material is a natural inorganic integral molding insulation material, using nitrile rubber (NBR), Polyvinyl chloride (PVC) and other raw materials are foamed through a process. It is suitable for medium temperature of minus 50℃~110℃, and its closed-cell structure has relatively good thermal insulation performance and low moisture-proof water absorption. Rubber-plastic thermal insulation materials have the following advantages: good thermal insulation effect, significant anti-condensation effect, and should be used as the outermost layer of thermal insulation pipes; flame-retardant, smoke-proof, safe and reliable; appearance is neat and beautiful; convenient installation and quick construction.

Scope of application:

rubber and plastic insulation materials are mainly used in the central air-conditioning and household air-conditioning and refrigeration systems of civil buildings. Insulation of refrigerant-carrying pipelines; insulation of condensate pipelines; insulation of automobile air-conditioning pipelines; insulation of various industrial large-diameter pipelines and cold insulation systems such as ships and aviation.

Construction process:

The pipeline shall be subjected to water pressure test before heat preservation, and pressure test and heat preservation shall be carried out after the water pressure test is qualified Work procedures are handed over to prevent heat preservation of water pipes that have not undergone pressure test and avoid work conflicts.

Material selection:

The greater the difference between the medium temperature in the system and the ambient temperature, the greater the thickness selected; the environment where the cold system is located The greater the relative humidity, the greater the thickness selected; when the diameter of the cold medium pipe is less than 150mm, the larger the pipe diameter, the greater the thickness selected; the less air in the engineering system, the greater the thickness selected.

Prevention and treatment of common quality problems:

The common problems of thermal insulation quality are mainly manifested in uneven application of glue, poor bonding of thermal insulation materials, and thermal insulation materials The thickness is incorrectly selected, the appearance type is not uniform, and the type is not beautiful. There are several main quality problems in the construction as follows:

(1) The insulation layer and the wooden support are not tightly bonded. During the construction, due to the inaccurate measurement of the length of the insulation layer by the workers, the workers often stretched the insulation materials before bonding. Because the material itself is elastic, it will shrink after stretching. After a long time, the glue between the insulation material and the wooden support will open. This is one of the most common quality problems in insulation —.

Prevention measures: Do not stretch the material during the cutting and bonding process, and require the wooden support Glue should be applied to both sides and the cross-section of the insulation material. The glue should be evenly and full; the wooden support should be selected regularly. If the wooden support is broken into several pieces, it must be replaced to prevent condensation due to cold bridges.

(2) The bonding between insulation materials is not tight. The bonding between insulation materials is relatively common, especially the long bonding seam between the insulation materials above the horizontal pipe and the side of the riser, which is prone to weak bonding. This is mainly caused by uneven cross-section and uneven glue application during the cutting process. This is also one of the most common quality problems in heat preservation.

Prevention measures: Require construction workers to use a ruler in the process of cutting materials, not bare hands. When applying glue, it is required to be even, and when bonding, start from one side and gradually squeeze hard to ensure that the cut surface of the material can be bonded firmly.

(3) Glue at the elbow. Generally, it is required to place the joints of the insulation layer above the pipeline during pipeline insulation, and cracking of the insulation layer often occurs above the elbow of the pipeline, which causes the local insulation layer to be too thin, causing condensation to condense.

Prevention measures: Require construction personnel not to cut materials based on the estimated size when doing elbow insulation. Use a soft tape to accurately measure the size; the cross section of the material to be cut should be flat; apply more glue to the place where the local force of the pipe elbow is large.

When insulating the elbow, try to use direct elbow heat preservation, that is, the bonding seam of the heat preservation layer follows along Pipe direction, instead of using cutting horseshoe-shaped multiple bonding to find the arc. This can save a lot of manpower, time and materials, and also ensure the quality of heat preservation, and at the same time, the appearance is more beautiful than the latter.

(4) The wall casing is skewed. In actual construction, it is prone to eccentric or eccentric placement of the casing pipe where the pipe penetrates the wall, so that the insulation layer cannot pass through the wall and cannot provide heat insulation.

Prevention measures: The casing is generally made directly by cutting the pipe during construction, according to the wall thickness and The plastering thickness determines the casing length. Before wall construction, use multiple wedge-shaped wooden strips to support the casing and fix it on the pipeline. When plugging the wooden strips, ensure that the casing is concentric with the pipeline. Remove the wooden strips during the thermal insulation construction, and then pass the thermal insulation layer through the casing.

(5) The finished product is destroyed. After the rubber-plastic insulation construction is completed, the insulation pipes close to the pedestrian passages are likely to be bumped and scratched by heavy and sharp objects.

Prevention measures: Use carton or thick plastic cloth to wrap tightly in the exposed area, and tie it with iron wire Strong, the packing box of rubber and plastic materials or fan coil can be used in construction. The protective layer should exceed the height that ordinary human hands can reach. The thermal insulation in the exposed new fan room and the exposed pipeline well should be postponed as far as possible until the other types of work are completed before construction, and strive to do it all at once.

The rubber and plastic insulation materials produced by Huizhou Ubipart Technology Co., Ltd. have excellent performance and are produced in the factory Strong ability and sufficient supply. The product range includes rubber and plastic pipes, coils, sheets, tapes, glues and pipe pallets, etc. We look forward to long-term cooperation with you!

Scan the QR code to read on your phone

-

Tel

-

E-mail

-

Message

-

top

Huizhou Bellsafe Up Technology Co., ltd.

Phone:020-85626465

Email:bellsafeup@163.com

Address: Fourth Industrial Zone, Shenli Village, Yuanzhou Town, Boluo County, Huizhou City

Copyright © 2021 Huizhou Bellsafe Up Technology Co., ltd. 粤ICP备15054146号 Power by www.300.cn