-

Rubber and plastic insulation material 3

-

Performance: technical parameters

Operating temperature: (-50)~110℃

Density: 40~60KG/ M3

Thermal conductivity: 0℃., ≤ 0.034W/M.K

Water vapor permeability: ≥10000

Oxygen index: ≥32%

Smoke density: ≤75%

Toxicity of burning smoke: quasi-safe ZA3 level qualified

Vacuum water absorption rate: ≤10%

Tear strength: ≥3.5N/cm

Dimensional stability: 105℃, 7 days≤10%

Compression rebound rate: compression rate 50%, compression time 72 hours ≥ 70%

Noise reduction value: up to 30 DB(A)

Ozone resistance: 202MPA ozone partial pressure, 20 hours, no cracking

Aging resistance: 150 hours, slightly wrinkled, no cracks, no pinholes, no deformation -

|

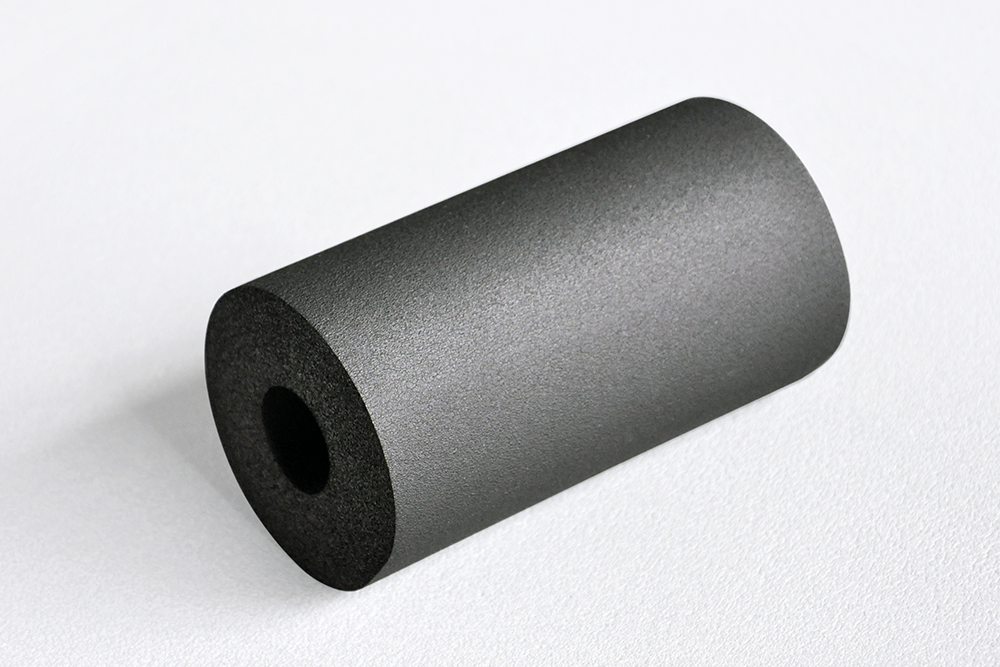

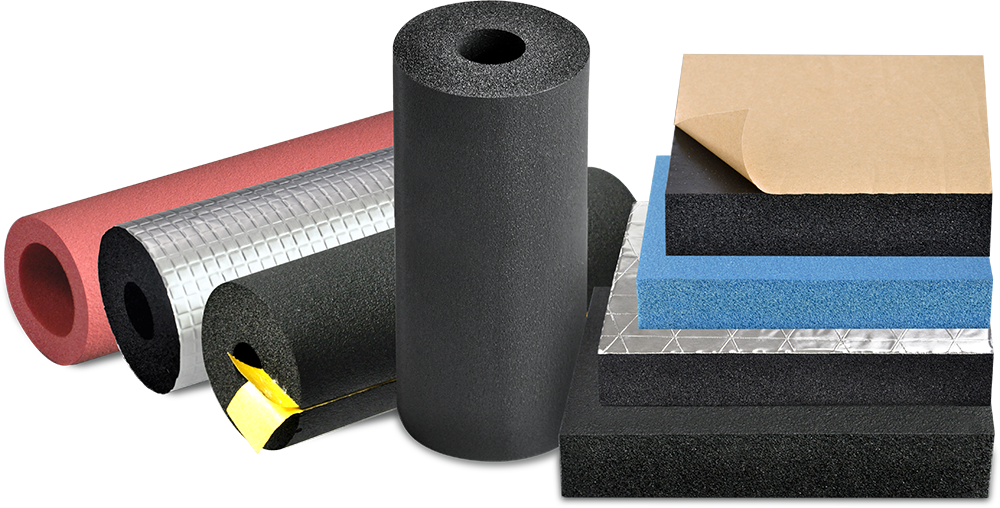

One. What is rubber and plastic insulation material Rubber and plastic materials It is a kind of high-quality rubber and polyvinyl chloride (NBR/PVC) as the main materials, after mixing, |

|

Second, the thermal insulation principle of rubber and plastic materials The insulation principle of rubber and plastic should follow Speaking of its structure: rubber-plastic material is a closed-cell foam material full of small bubbles processed through a series of processes. Because the bubbles inside are closed, it is similar to a static gas without convection, and the thermal conductivity is very high. Low (approximately 0.0267W/(m·k) at 20°C), which can reduce the heat conduction between the container or pipeline and the external environment, thereby playing the role of heat preservation/cooling. This is the main insulation principle of rubber and plastic insulation materials.

|

|

|

Three. Function rubber and plastic materials It is a kind of elastic closed-cell foam material, which has the advantages of low thermal conductivity, fire-retardant, moisture-proof and moisture-proof, vibration reduction and noise reduction, environmental protection and health, long service life, elegant and beautiful appearance, and convenient installation. It is widely used in central air-conditioning, construction, chemical industry, medicine, textile, metallurgy, shipbuilding, automobiles, electrical appliances and other related cold and heat medium pipes or containers, which can achieve the effect of reducing cold and heat loss. In addition, the construction is simple, the appearance is neat and beautiful, and the product does not contain fiber dust, and does not breed harmful substances such as mold, so it is a high-quality heat insulation material. |

|

Four. Practical application rubber and plastic as a thermal insulation material , With its excellent heat preservation/cold performance, it is widely used in cooling/heating systems. In addition, rubber and plastic heat preservation materials can also prevent condensation, and are widely used in the field of central air conditioning: mainly used in air conditioning systems Insulation of air ducts and pipelines, indoor air-conditioning pipelines need to be insulated throughout the entire process. Pipe fittings, valves, and metal fittings in contact with the pipeline should be wrapped with insulation materials, especially the weak links at the joints of insulation materials, pipeline fixing points, valves, etc. . Rubber and plastic insulation materials are used in construction, The insulation application of industry, pipelines and equipment is suitable for cold insulation of various refrigeration engineering projects. Including the energy and chemical industry, textile industry, metallurgy, electrical appliances and other industries in various cold and heat medium pipelines and containers, as well as ships, automobiles and other rail transit fields, the application of rubber-plastic plates or rubber-plastic pipes to reduce cold The purpose of damage and heat damage. Rubber and plastics can not only be used in industrial pipelines , Equipment insulation comes in handy, and rubber and plastic can also play a sound absorption and noise reduction effect! Rubber and plastic can be used for sound insulation of building wall panels, sound absorption of air ducts and sound absorption decoration of entertainment venues. It is also widely used in the field of noise reduction; it can also be used for impact resistance and decompression of instruments and equipment. |

|

|

Five. Main indicators of rubber and plastic insulation materials The main performance indicators to measure the pros and cons of rubber-plastic insulation materials are: thermal conductivity of rubber-plastic insulation materials , Moisture permeability, combustion performance and tear strength. 1, thermal conductivity< /p> The guidance coefficient is the most basic performance index of thermal insulation materials, which determines the thermal insulation performance of the material. The smaller the coefficient, the better the thermal insulation performance of the material. On the contrary, the larger the coefficient, the material will basically not achieve any thermal insulation/cold insulation effect, and it will also cause a large amount of energy loss. In a 0℃ environment, the thermal conductivity is The material with only 0.032W/(m·k) is already an ideal insulation material. 2, moisture permeability The moisture permeability reflects the water vapor permeability of the material, that is, the material’s resistance to water vapor penetration Ability. The stronger the resistance to water vapor penetration, the longer the service life of the material. There are two important indicators of moisture permeability: moisture resistance factor and moisture permeability coefficient. Moisture permeability coefficient: refers to the plate-shaped per unit thickness per unit area under certain temperature and humidity conditions The water vapor flow rate of the material. Moisture resistance factor: Generally, the moisture permeability of the material can pass the tested moisture permeability coefficient Determine the moisture absorption rate of the material, but the absolute value of the moisture permeability coefficient obtained by the test is very small, the unit is complex, and it is directly related to the local atmospheric pressure, so the material science derives the index value of the moisture resistance factor, which can be directly based on Its size is used to judge the water vapor permeation resistance of the material. The larger the moisture resistance factor, the stronger the product's ability to block water vapor, and reaching more than 20,000 is equivalent to completely blocking water vapor penetration. 3. Combustion performance< /p> According to the latest national standard GB8624-2012, the combustion performance of building materials is divided into the following levels: Class A is non-combustible, B1 is non-combustible, B2 is combustible, and B3 is flammable. Except for traditional inorganic materials that can reach A-level, all other products on the market are in B1 Below the level, that is to say, to ensure the safety of rubber and plastic insulation materials after use, the combustion level must reach B1, which is the minimum requirement. Compared with traditional inorganic materials, the biggest advantage of rubber-plastic insulation is its installation performance. Although the traditional inorganic material rock wool has the fireproof performance of Class A otherwise, its water absorption rate is large, and the water is easy to accumulate in the rock wool board, which will increase the weight of the insulation layer for a long time, causing the insulation layer to fall off, and the repair rate is high. At the same time, the material installation The process is complicated, and it is difficult to do a complete fit between the seams, resulting in increased labor costs and great waste. 4. Tear strength Tears are caused by cracks or cracks in the material that rapidly expand and crack when stressed Phenomenon, this is one of the characteristic indexes to measure the resistance to destruction of rubber and plastic products. Compared with traditional inorganic materials, the advantage of Flexibility, high tear resistance, easy and convenient installation. |

Online Inquiry

Contact information

-

Tel

-

E-mail

-

Message

-

top

Huizhou Bellsafe Up Technology Co., ltd.

Phone:020-85626465

Email:bellsafeup@163.com

Address: Fourth Industrial Zone, Shenli Village, Yuanzhou Town, Boluo County, Huizhou City

Copyright © 2021 Huizhou Bellsafe Up Technology Co., ltd. 粤ICP备15054146号 Power by www.300.cn