Count down several key performance indicators of rubber and plastic insulation materials

- Categories:Company News

- Author:

- Origin:

- Time of issue:2021-08-16 09:22

- Views:

(Summary description)Rubber and plastics are made of NBR and PVC as the main materials, and are made of flexible heat preservation and heat insulation materials through banburying, open refining, extrusion, vulcanization foaming, cooling and other processes. The coefficient can be as low as 0.032w/(m·k), which can effectively reduce the heat conduction between the container or pipeline and the external environment, thereby playing the role of heat preservation/cooling.

Count down several key performance indicators of rubber and plastic insulation materials

(Summary description)Rubber and plastics are made of NBR and PVC as the main materials, and are made of flexible heat preservation and heat insulation materials through banburying, open refining, extrusion, vulcanization foaming, cooling and other processes. The coefficient can be as low as 0.032w/(m·k), which can effectively reduce the heat conduction between the container or pipeline and the external environment, thereby playing the role of heat preservation/cooling.

- Categories:Company News

- Author:

- Origin:

- Time of issue:2021-08-16 09:22

- Views:

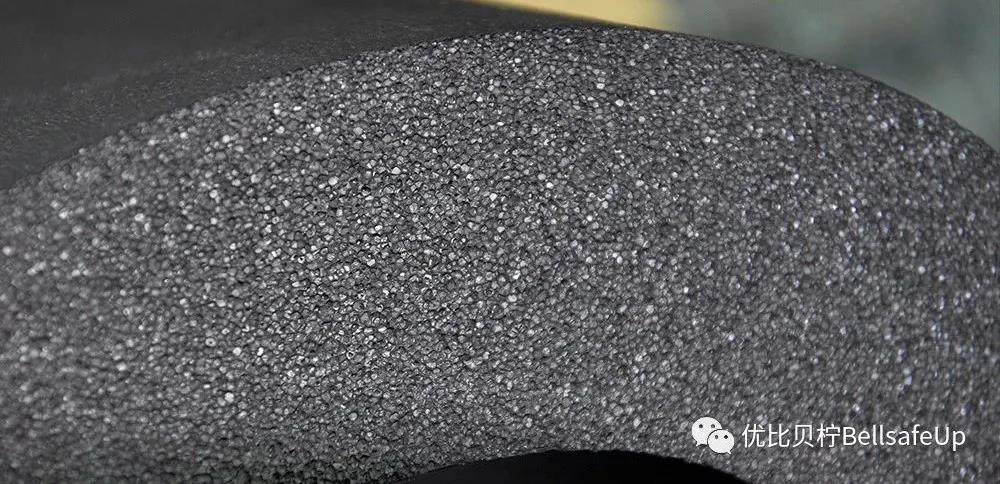

One. Rubber and plastic materials

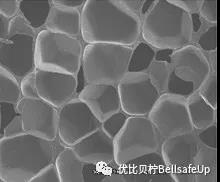

Rubber and plastics are made of NBR and PVC as the main materials, and are made of flexible heat preservation and heat insulation materials through banburying, open refining, extrusion, vulcanization foaming, cooling and other processes. The coefficient can be as low as 0.032w/(m·k), which can effectively reduce the heat conduction between the container or pipeline and the external environment, thereby playing the role of heat preservation/cooling.

Two. Application field

Rubber and plastic materials are environmentally friendly and non-toxic thermal insulation materials with excellent performance due to their advantages such as heat insulation, moisture resistance and mildew resistance, fire resistance and flame retardancy, environmental protection and non-toxicity, vibration reduction and noise reduction, and softness and elegance. Widely used in the following fields:

1. Central air-conditioning duct/water pipe insulation;

2. Building wall insulation;

3. Indoor sound insulation and shock absorption;

4. The hospital is clean and mildew-proof;

5. Industrial dust-free workshop;

6. Vibration damping and buffering of instruments and equipment.

Three, the key performance indicators of rubber and plastic insulation

The main performance indicators to measure the pros and cons of rubber and plastic insulation materials are:Thermal conductivity λ, moisture resistance factor μ, combustion performance.

1. Thermal conductivity λ

Thermal conductivity is the most important performance index of thermal insulation materials, which determines the thermal insulation performance of the material, and it is represented by "λ" in materials science. The smaller the thermal conductivity, the better the material's thermal insulation/cold insulation performance. On the contrary, the larger the coefficient, the worse the insulation/cold insulation effect of the material, which not only fails to achieve the insulation effect, but even causes a large amount of energy loss.

In the 0℃ environment, the thermal conductivity of Ubisoft rubber and plastic insulation material is as low as 0.032W/(m·k), which is an ideal insulation material.

橡塑发泡材料气泡微观结构

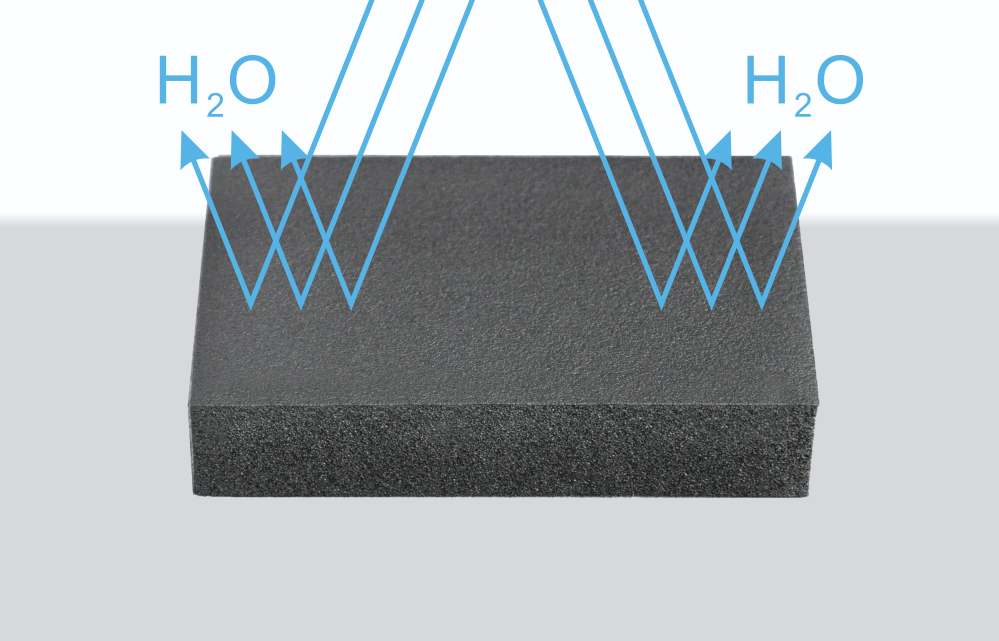

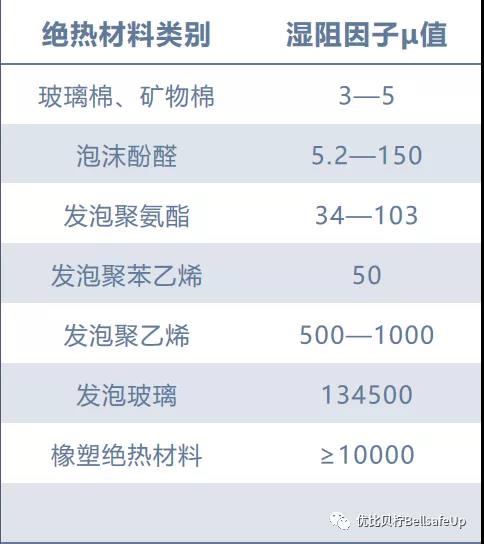

2. Moisture resistance factor μ

The moisture resistance factor is an index that measures the ability of a material to resist water vapor penetration, and it is represented by "μ" in the industry. The larger the moisture resistance factor, the stronger the product's ability to block water vapor; the stronger the ability to resist water vapor penetration, the longer the service life of the material.

In general, the moisture permeability of the material can be determined by testing the moisture permeability coefficient of the material, but the absolute value of the moisture permeability coefficient obtained by the test is very small, the unit is complex, and it is directly related to the local atmospheric pressure, so the material science leads Based on the index value of the moisture resistance factor, the water vapor permeation resistance of the material can be judged directly based on its size. When μ reaches more than 20,000, it is considered to be completely isolated from water vapor penetration.

3. Combustion performance

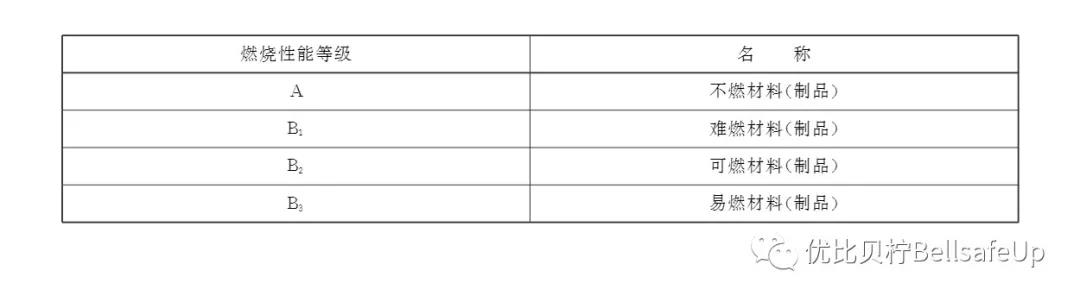

The latest national standard (GB8624-2012) divides the combustion performance of building materials into A, B1, B2, and B3 grades.

The higher the combustion performance level, the better the flame retardancy and the higher the fire safety.

Except for the traditional inorganic materials that can achieve Class A non-combustibility, other insulation materials on the market are all at or below the B1 level. The "Code for Fire Protection Design of Buildings" (GB50016-2014) has clear requirements for fire protection grades of building insulation materials. For fire safety considerations, the combustion performance level of insulation materials should not be lower than B1 level.

Although traditional inorganic materials (such as rock wool) have Class A fire resistance, their water absorption rate is large, and moisture is easy to accumulate in the rock wool board, which causes a serious decline in insulation performance, and will increase the weight of the insulation layer for a long time, causing the insulation layer to fall off. The repair rate is high. At the same time, the material installation process is more complicated than that of rubber and plastic, and it is difficult to make a complete fit between the board seams, resulting in an increase in labor costs and a reduction in thermal insulation effect.

。

Compared with traditional inorganic materials, the biggest advantage of rubber and plastic insulation materials lies in its excellent and long-lasting and stable insulation performance.

In summary, rubber and plastic is an excellent thermal insulation material. When selecting rubber and plastic insulation materials in energy-saving and environmental protection systems, the most important thing to pay attention to is the thermal conductivity λ, the moisture resistance factor μ, and the combustion performance.

Scan the QR code to read on your phone

-

Tel

-

E-mail

-

Message

-

top

Huizhou Bellsafe Up Technology Co., ltd.

Phone:020-85626465

Email:bellsafeup@163.com

Address: Fourth Industrial Zone, Shenli Village, Yuanzhou Town, Boluo County, Huizhou City

Copyright © 2021 Huizhou Bellsafe Up Technology Co., ltd. 粤ICP备15054146号 Power by www.300.cn